Polymers in Building: Stronger, Less heavy, and Extra Durable

Making Best Use Of the Prospective of Polymers: Discover the Multifaceted Advantages and Practical Utilizes

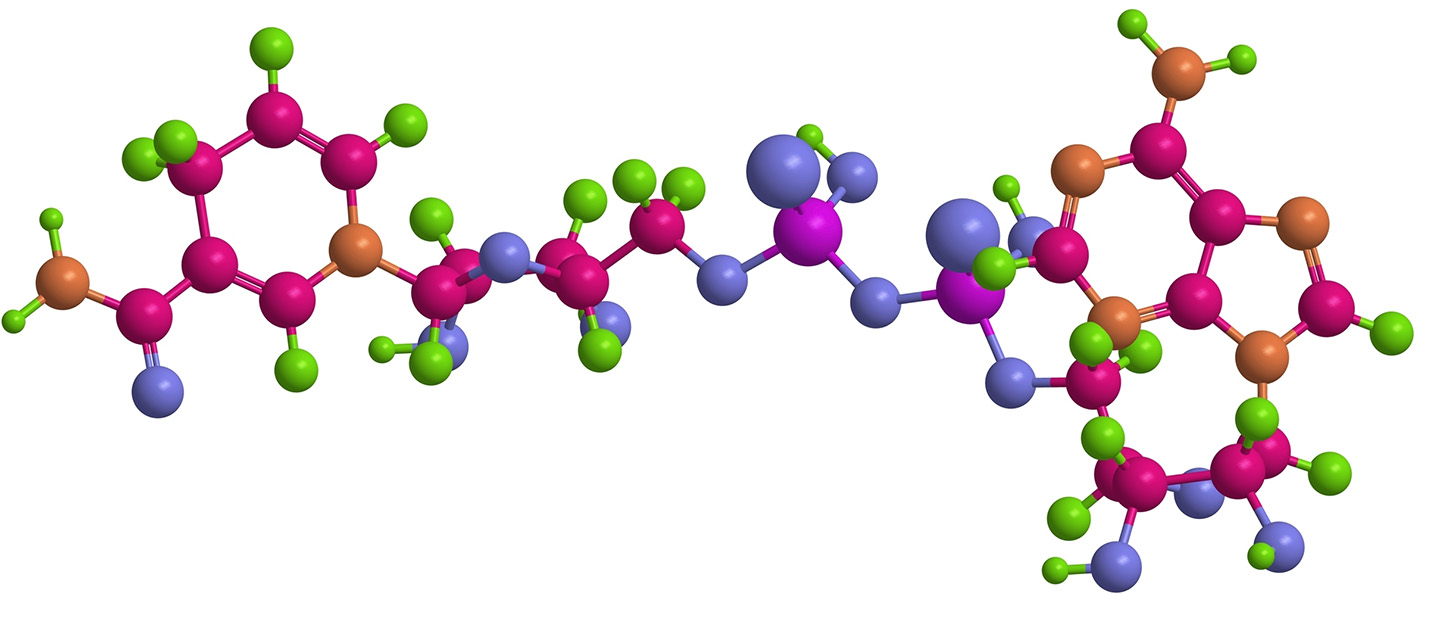

In the vast landscape of product science, polymers stand apart as versatile compounds that have penetrated almost every element of modern life. Their application spans various sectors, from manufacturing and building to healthcare and innovation. The diverse advantages and useful usages of polymers remain to evolve, providing cutting-edge services to complicated obstacles. By checking out exactly how polymers can enhance product longevity, drive sustainability efforts, revolutionize medical care remedies, and pave the way for future technical improvements, we can uncover a globe of possibilities waiting to be harnessed.

Relevance of Polymers in Modern Industries

Polymers play a critical duty in modern-day markets, offering as flexible products that drive innovation and performance throughout a broad range of industries. The electronics sector benefits from the insulating properties of polymers, essential for producing circuit boards and digital devices. Their adaptability, durability, and cost-effectiveness make polymers vital in contemporary manufacturing processes, cultivating improvements and driving progression in different markets worldwide.

Enhancing Item Toughness With Polymers

With a concentrate on durability and strength, integrating advanced polymer innovations right into item design has come to be a keystone of enhancing longevity in modern production procedures. Polymers provide a wide variety of residential or commercial properties that add to the general resilience of products. One essential advantage is their resistance to corrosion, chemicals, and weathering, making them perfect for usage in different markets where direct exposure to harsh conditions is typical.

Furthermore, polymers can be tailored to meet specific durability requirements, permitting producers to personalize items according to their intended usage and expected life-span. By incorporating polymers right into item parts, makers can enhance stamina and influence resistance, minimizing the chance of damage or wear gradually.

Additionally, polymers are light-weight yet durable, supplying longevity without including unneeded weight to items. This characteristic is especially useful in sectors such as aerospace and vehicle, where lightweight materials are important for improving gas effectiveness and overall performance.

Sustainability Developments Through Polymer Innovation

In the realm of contemporary manufacturing and item layout, the cutting-edge application of polymers is driving significant developments in sustainability practices. Polymer advancement plays a critical role in boosting sustainability by offering options that minimize environmental impact throughout numerous industries.

Additionally, advancements in polymer technology have actually resulted in the production of bio-based and sustainable polymers, originated from all-natural resources such as plants, that use an even more sustainable choice to typical petroleum-based plastics. These environment-friendly polymers not only help in reducing dependence on fossil fuels but likewise reduce greenhouse gas exhausts during manufacturing. By incorporating these ingenious polymers into making processes, firms can minimize their environmental impact and relocate in the direction of even more sustainable methods, aligning index with international read initiatives to deal with climate change and promote a circular economy.

Polymers in Medical Care: Revolutionizing Medical Solutions

Among the crucial areas where polymers are making significant strides is in the development of targeted medication distribution systems. By enveloping medicines within polymeric nanoparticles or micelles, scientists can enhance medication security, enhance bioavailability, and enable controlled release, causing extra effective therapy regimens with decreased side results.

In addition, polymers are crucial in the area of regenerative medicine, where they are used to produce scaffolds that simulate the extracellular matrix, providing assistance for cell growth and cells regeneration. This modern technology holds immense pledge for repairing damaged organs, advertising injury healing, and progressing personalized medicine methods.

Basically, the assimilation of polymers in healthcare is driving advancement, boosting therapy efficiency, and ultimately boosting individual results in methods formerly assumed unattainable.

Future Applications and Developments in Polymer Technology

Advancing at the forefront of clinical exploration, polymer innovation continues to lead the means for groundbreaking applications and developments shaping diverse sectors. In addition, polymer nanocomposites are improving the mechanical and thermal buildings of products, leading to stronger and lighter components in aerospace and auto markets. Looking in advance, researchers are checking out the potential published here of shape-memory polymers for applications in robotics and biomedical tools, where materials that can "remember" and return to their original forms provide interesting possibilities for innovation.

Conclusion